Feel Lifted UP

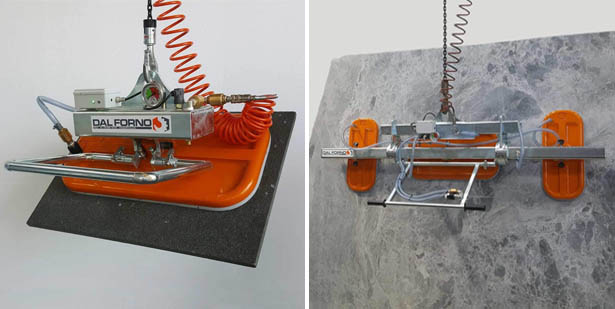

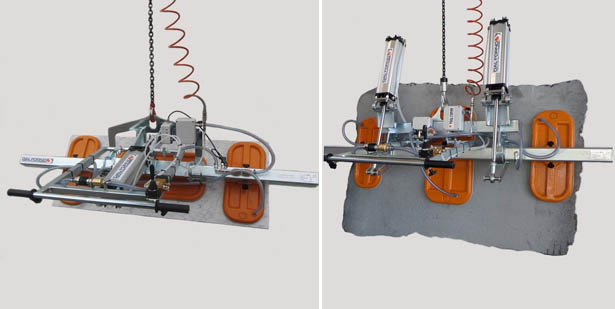

Complete supplies of lifting and handling equipments, including suction pads for the stone industry, Jib cranes, overhead suspended systems, electric chain hoists, vacuum lifters and material handling equipments. Our products are designed according to the most valuable quality standards and supported by many years of experience on the field.

A leader company for lifting and handling equipments, starting from its great experience acquired in more than fifty years of working, is able to offer its competence in finding quick solutions to satisfy the requirements and needs of the customers. Provides vacuum lifters, column cranes and bracket cranes; electric chain hoist and rope hoists; overhead suspended lifting systems and handling devices: clamps, suction pads, manipulators, vacuum generators.

MATEC specializes in the design and development of waste water purification and filtration plants. We work for many different industries, the most important are: mining, aggregates, gravel, sand, stone, ceramics and glass. Our mission is the customer’s satisfaction. That is why we offer timely after-sale service, as well as before-sale advice to understand the real requirements of our potential customers.

MATEC new plants are based in Massa, in the very heart of a wide industrial zone, also known as Apuana. We have installed over 250 purification plants all across the world in the last two years: this is the real guarantee of our production and service quality. We develop ourselves all-inclusive purification and filtration plants. All the machines are built in our plants. Thus we can offer top-quality products ‘Made in Italy’, which will fulfill the most demanding applications and markets.

Matec offers the Kompact plant which guarantees the quality of big plants to serve small-size companies. It is designed for users who have water flows which range from 200 to 700 l/min, and whose limited storage space demands very compact sludge. Everything is integrated into the plant framework and the clear water tank and the silo decanter are combined.

Few of the components of the recycling plant are:

POWER LIFTING TECHNOLOGY SINCE 1925

Our company has been active on the trade-market as a producer of lifting machinery branded O.C.M.A. since 1925. This date is a reason of pride for us, since it makes us one of oldest and more experienced companies in this field. We are specialised in the production of gantry crane (box and tristle), bridge crane and flag crane.

In the last few years we have been improvinf and optimizing our products, in fact we have been focussing on designing and realizing special machines. We have been doing this through the employment of the most updated technologies, which allowed us to develop and potentiate both the technical and mechanical components of our machines. In this way we have been able to fulfil succesfully the always more demanding and specific request of our customers. Starting off with the elaboration of raw materials, the whole of our production cycle is carried out completely inside aur factory and exactly this, is the guarantee of an accurate and continuous control on our products.

In recent years great attention has been directed also to the Natural Stone industry and in first place to the problems strictly linked to it such as maximum utilization of the space available, long-life and highly reliable components, without leaving aside any other crucial sectors of the market anyway.

Our field of action is nowadays spread out world-wide. We have customers based in Asia, Europe, Africa, North America. Apart from this, we also point out that on the national level we supply factories in the most competitive and qualified areas.

OCMA is:

GAM S.r.l. is a company founded by members who have acquired a multidecadal experience in the field of construction machinery and equipment for the processing and handling of marble slabs, granite, conglomerate and stone in general.

Great attention has been paid to tangential heads for grinding and polishing granite, conglomerates and porcelain granite. In addition, great attention has been devoted to the creation of innovative calibration system for all sizes of slabs, strips and tiles, which combine high accuracy of the thicknesses obtained and feed speed with unmatched operating costs, so low for both energy consumption and maintenance.

Range of Products available with us:

Tangentinal Head for Polishing machines:

Diameter 920mm and 1080mm with Tilting angle upto (+/-)12°

Granite polishing for tiles: 8 to 22 heads - 650mm to 850mm

Calibration for tiles: 1 to 4 spindles

Calibration of Slabs: 600mm to 2100mm