Huada Superabrasive Tool Technology Co.,Ltd.,owns excellent R&D team and Production Managing team,specialising in diamond tools and stone quarry equipment industry.

Huada specializes in producing all assorted of Quarrying Machines, including various of Wire Saw Machine, series of Multifunctional Drilling Machine especially Multifunctional Rock Driller Machine,Horizontal Core-boring Machine and etc.

Take Wire Saw Machine as an example, with a huge sum of investment and strict quality inspection, after tested in the quarries again and again, our Wire Saw Machine has realized quarry automatically (included adjusting linear speed and controlling track automatically), which has been exported to Italy, Germany, Russia, Japan, Brazil, Indonesia, South Africa, Iran etc.

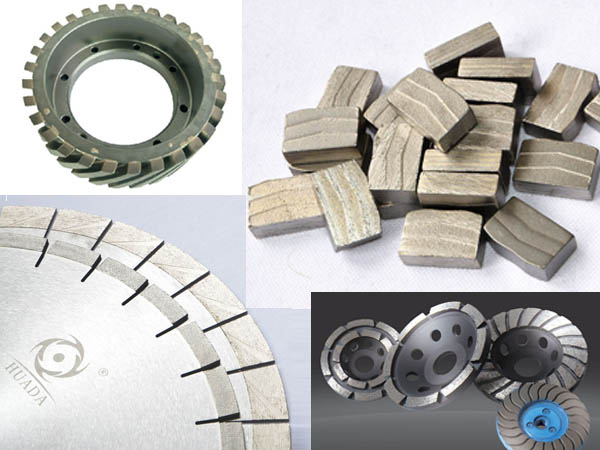

Our company also manufacture all kinds of diamond tools, which are including diamond blades, segments, especially gangsaw and multi-blade segments, grinding blocks, cup wheel, diamond wire saw for quarry and workshop, etc. We offer the excellent Diamond Wire Saw to all over the world.

Performance Tools

Diamond Saw Blade and Segments

Diamond Wires - 7.3mm, 8.3mm for multiwire machines

Diamond Wires - 8.3mm and above for all other machines and quarry

Metal Bond for polishing - Fickert and Frankfurt types

Resin Bond for polishing - Fickert and Frankfurt types

Diamond Grinding Cup Wheels

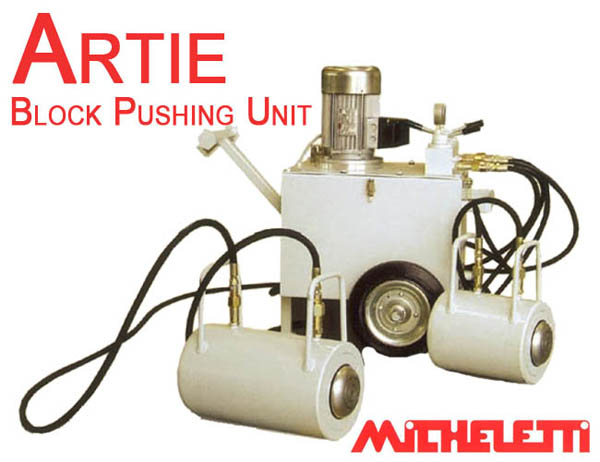

Single Wire machines

Quarry Machines

KWEZI srl, a leading manufacturer of quarrying and processing machines for granite, marble and stones, is located in the World’s oldest source of Dimensional Stone extraction, Carrara, Italy.

The philosophy of KWEZI srl is to satisfy all the needs of the “Universe of Stone”. Whether the request is from a small company with a single specific need, or from a large corporation requiring a complete system, like in South Africa, Spain and Brazil, KWEZI srl always offers its Clients the ideal solution to problems encountered in natural stone quarrying and processing, by combining technological know-how and innovative techniques with years of “in the field” experience.

From a single machine, to a “Turnkey” processing line, KWEZI srl can solve any production need of the Stone Industry with the latest technological advances, but not only.

KWEZI srl also provides consultation services to advice on the potential of a quarry, geological prospecting, detailed analysis of the deposit and the type of equipment required for the most efficient method of extraction.

The services that KWEZI srl provides to his Customers are not completed with the sale, but accompany and follow the goods supply, KWEZI srl in fact is able to offer to Customer’s staff the necessary theoretical and practical training regarding the purchased machines. Upon request the training can be carried out at Customer’s factory by skilled technicians who are able to assist the Customer during machines starting phase, in order to transfer the precious know-how which is indispensable to use them properly.

The philosophy of KWEZI srl is to supply high quality machines, constantly improving their features and reliability, but even the best machines need technical assistance and for that reason KWEZI srl has organized a prompt and efficient after-sale assistance service which allows to satisfy the requests of the Customers all over the world.